Wet coating

Wet coating or powder coating?

What is wet painting?

V coat has extensive experience wet painting or spray painting is a process in which several liquid paint layers are applied to the product. It can be a combination of different types of layers, with each layer fulfilling its specific function. Wet coating is available in all conceivable colours. Any desired finish is possible: matt, gloss or high gloss. Wet coating can be applied to various surface structures. From applications on steel, aluminium, zinc, stainless steel or copper. But also on plastics such as PVC, ABS, SMC, Polycarbonate and many more. Besides extensive experience with standard polyurethane coatings, we are also very familiar with special wet-paint coatings. Phosphor lacquers, Nextel lacquers, Soft-touch lacquers, heat-resistant coatings, anti-graffiti varnishes, EMI shielding lacquers and electrically insulating lacquers are some examples.

Atelier V coat - 2 wet paint lines

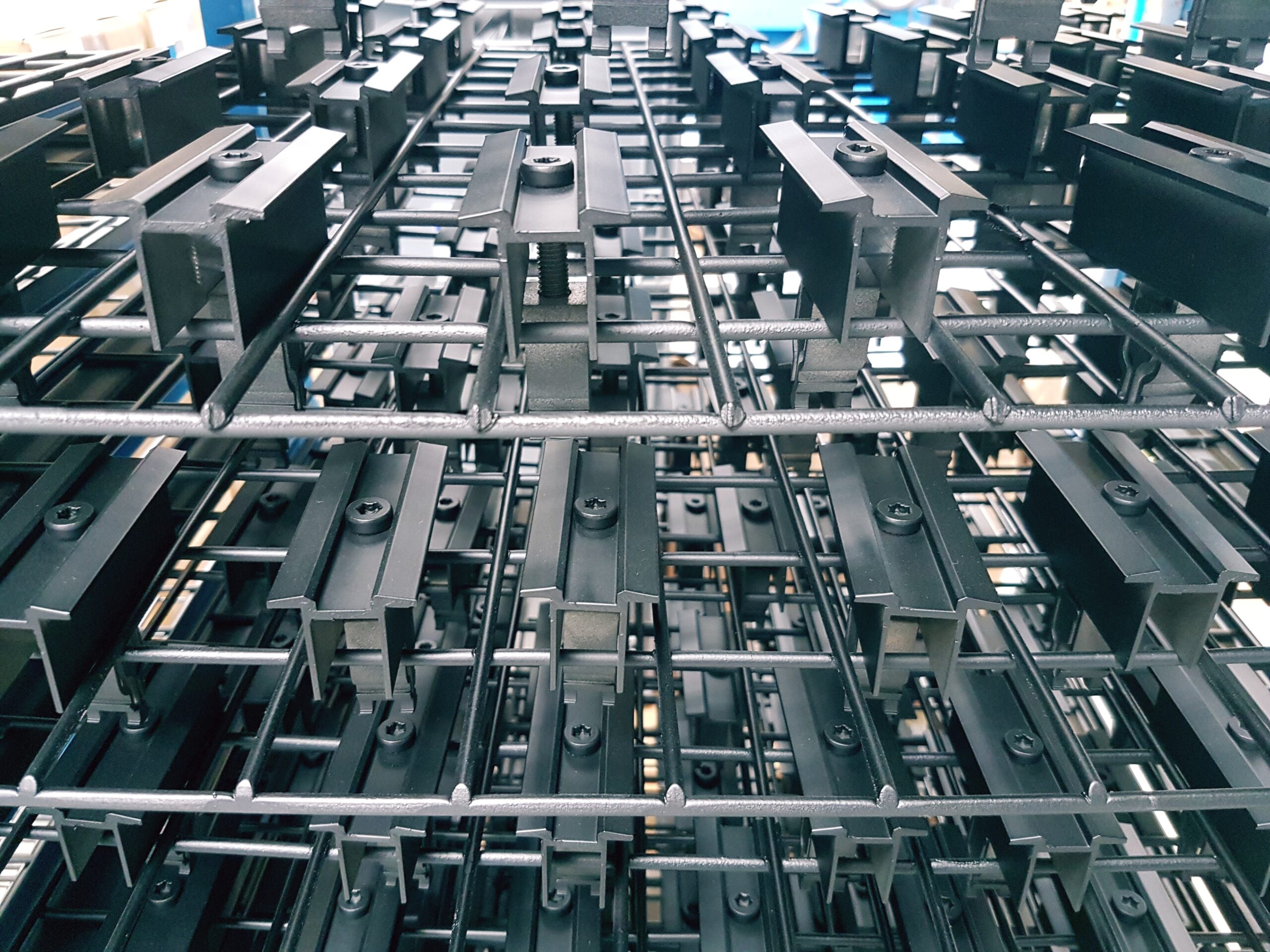

Series or custom-made? We treat your products within the shortest possible lead time. In V coat’s workshop, we have 2 wet-paint lines The first wet-paint line is a fully autonomous painting line with chemical pre-treatment where the products are very thoroughly cleaned with a power wash installation. In the wet-paint cabin, both decorative and anti-corrosion paints can be applied to steel and plastic, which are then baked in the integrated baking oven. The second wetpainting line is also a fully autonomous paint line with chemical pre-treatment where the products are very thoroughly cleaned with a power wash installation. This wet-paint line consists of a wet-paint cabin where highly heat-resistant lacquers can be applied (e.g. on exhaust systems, heaters, etc.) and an integrated baking oven that dries the lacquers by forced drying to a temperature of 180 °C. This paint line is also connected to powder line 2 so that blasted parts can be finished with powder coating, if necessary, instead of wet paint.

Atelier V coat - 3 wet-paint booths

Wet-paint booth 1 is extremely suitable for products requiring a very high degree of finish. This booth is fully pressurised and has its own pre-treatment zone and drying room. The products do not leave the conditioned areas until they are completely finished. Naturally suitable for metal and plastic. We use wet-paint cabin 2 for products that require several layers for high corrosion protection (class CM5). Wet coating booth 3 is used for applying special technical coatings such as EMC shielding (nickel or copper) to plastics.

Other services

Powder coating

Powder coatings are environmentally friendly and stand for scratch-resistant results. Powder coating applies to all kinds of ferrous metals. V coat does it all with a structural focus on quality.

Printing

V coat has a wide range of options in surface treatment techniques and therefore also in printing. As a final finish, we can also print or print on your coated products or painted parts. V coat provides a total solution through various in-house printing techniques.

Pretreatment

The quality of powder or wet-lacquer coating stands or falls with proper and thorough pre-treatment of the materials. Only then will you get an even, scratch-resistant and beautiful end result.

EMI shielding

Electronic products receive a lacquer that ensures protection against external electromagnetic interference.

Assembly

V coat unburdens you as much as possible by also providing small assembly works, thus streamlining your process.

Anti-corrosion coating

V coat also offers the solution for highly durable coatings. One of the sister companies within the group, Van Os-Duracoat, specialises in thermoplastic coatings.